Heat Strengthened Glass

Product Details:

- Bent Tempered Available

- Flat Tempered Available

- Transparency High

- Features Enhanced safety, improved mechanical strength, thermal stability

- Tolerance 0.2mm

- Structure Single Layer

- Strength Twice as strong as annealed glass

- Click to View more

Heat Strengthened Glass Price And Quantity

- 2200 INR/Square Meter

- as per requirement Square Meter

Heat Strengthened Glass Product Specifications

- 4mm to 19mm

- 0.2mm

- 2.5 Gram per cubic centimeter(g/cm3)

- Heat Strengthening

- Heat Strengthened

- Twice as strong as annealed glass

- Single Layer

- Clear

- Silica Sand, Soda Ash, Limestone

- Clear/Plain

- Available

- Varies with thickness

- Float glass

- Available

- High

- Enhanced safety, improved mechanical strength, thermal stability

- Smooth

Heat Strengthened Glass Trade Information

- 100 Square Meter Per Week

- 1 Week

Product Description

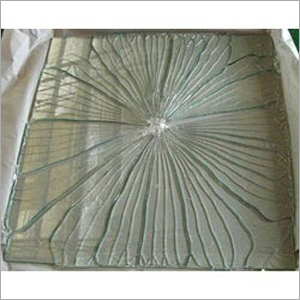

Heat Strengthened Glass

Driven by technology and quality, we manufacture, supply and export an enthralling range of Heat Strengthened Glass. Our offered range of glass exhibit various features such as durability, long life, crack resistance and rugged designs. Apart from this, we also provide customization of our offered range in terms of sizes, shapes and dimension as per the requirement of our esteemed clients. Our Heat Strengthened Glass is manufactured by using high grade materials in accordance with the quality standards.

Product Details

|

Structure |

Solid |

|

Features |

Superior glass,Chemical resistance,Surface compression |

|

Technique |

Laminated Glass,Tempered Glass |

Product Specifications

- Material: Aluminum, Silver

- Size: As desired

- Glass type: Float Glass

Product details

|

Material |

Glass |

|

Technique |

Laminated Glass |

|

Thickness Range |

10 mm |

|

Usage/Application |

Home, Office, Shops, Etc |

|

Brand |

Birkan |

|

Color |

Transparent |

|

Features |

Superior Glass, Chemical Resistance,Surface Compression |

Superior Strength & Safety

Engineered to be twice as strong as annealed glass, Heat Strengthened Glass presents increased resistance to mechanical shock and thermal stress. Its larger breakage fragments ensure added safety, making it suitable where durability and security are essential.

Versatile Applications

Ideally suited for facades, partitions, doors, and window systems, this glass accommodates a wide range of architectural needs. The available sizes and thicknesses, along with options for flat or bent tempered finishes, provide flexibility for both commercial and residential projects.

Advanced Thermal & UV Performance

With the ability to endure up to 250C and enhanced UV protection up to 99% with special coatings, this glass is perfect for environments that demand thermal stability and protection from ultraviolet rays. The smooth, high-transparency surface maintains clarity and aesthetics.

FAQs of Heat Strengthened Glass:

Q: How is heat strengthened glass produced and what makes it different from fully tempered glass?

A: Heat strengthened glass is produced by heating float glass to a high temperature and then cooling it at a controlled, moderate rate. This process makes it roughly twice as strong as annealed glass but less strong than fully tempered glass, resulting in larger fragments upon breakage.Q: What are the size and thickness options available for heat strengthened glass?

A: This glass can be manufactured in sizes ranging from 300mm x 300mm up to 2400mm x 5000mm. Thickness options range from 4mm to 19mm, with a size tolerance of 0.2mm, suitable for various structural and design requirements.Q: In which applications can I use heat strengthened glass?

A: Heat strengthened glass is ideal for use in facades, windows, partitions, and doors in both commercial and residential settings due to its enhanced safety, mechanical strength, and thermal stability.Q: What color and surface finish options are available for this glass?

A: The glass is offered in clear, extra clear, and tinted colors, with surface options including smooth finishes and edgework like polished or beveled edges. Special UV-protective coatings can further enhance performance.Q: How does heat strengthened glass benefit building projects?

A: It provides enhanced safety, improved mechanical strength, and thermal stability, helping protect occupants and structure integrity. The glass also offers high transparency and UV protection, contributing to energy efficiency and occupant comfort.Q: What materials and techniques are used in the production of heat strengthened glass?

A: Made from float glass composed of silica sand, soda ash, and limestone, the technique of heat strengthening involves controlled thermal processes to develop its unique properties. The final product features high clarity and a smooth, clear/plain pattern.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

We Mainly Deal in Major States like Rajasthan, Himachal, Punjab, Uttarakhand, Delhi, Madhya Pradesh, Haryana......

Registered & Marketing Office:

E-2B, Madhu Vihar, I.P. Extension Patparganj, Delhi - 110092

Send Inquiry

Send Inquiry Send SMS

Send SMS